(only available for certain terminals with 16-

or 32-bit CPU and a special firmware variant)

(only available for certain terminals with 16-

or 32-bit CPU and a special firmware variant)

-

-

Introduction to the CAN Logger Configuration / File Conversion Utility

-

Usage of the CAN Logger Configuration

Utility

-

Starting the CAN Logger Utility

-

Selecting the target hardware

-

The CANdb Import / Signal List Tab

-

Searching for signal names

-

The "Signal Info" display

-

The CAN-Message-Layout-Display

-

The Logged Messages Tab

-

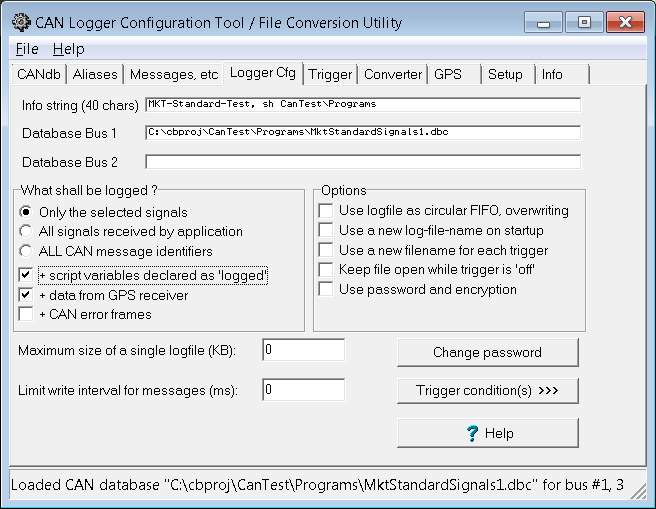

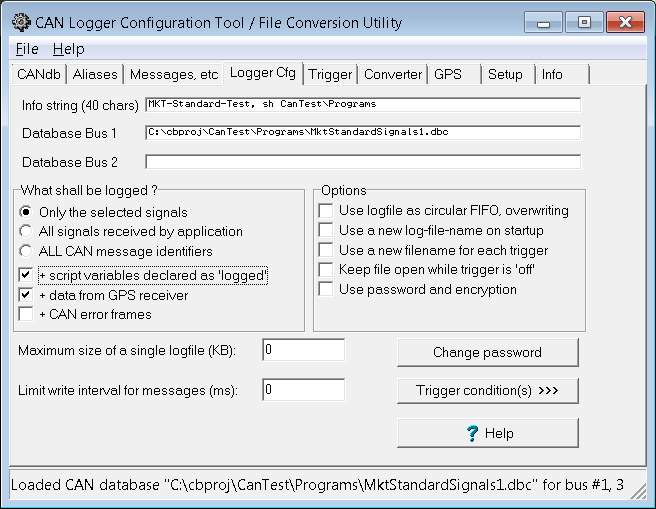

The Logger Configuration Tab

-

Trigger

-

The Trigger State Machine

-

Pre- and Posttrigger

-

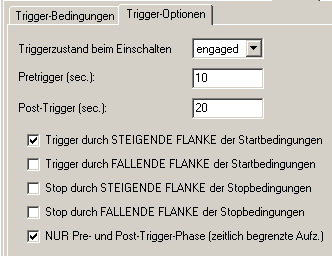

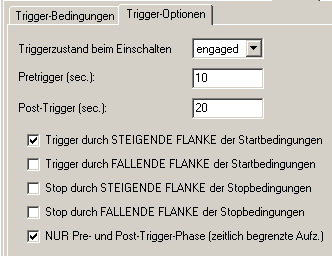

The Trigger Option Tab

-

The Trigger Condition Tab (for MKT-View

I )

-

The Trigger Condition Grid (for MKT-View

II )

-

Logging CAN messages which are not defined

in a CANdb file

-

Logging GPS (navigation) data

-

Logging other data (no CAN messages)

-

Saving the logger configuration file

-

Changing file- and directory names

-

Usage of the CAN Logger

-

Logging and analysis cycle

-

The power-good flag (and why we had to implement it)

-

Usage of the CAN Logfile Converter

-

Conversion parameters

-

Other converter options

-

Options to convert GPS data

-

The Graphic Preview Window

-

Notes on DIAdem

-

Known Issues

-

Limitations

-

Appendix

-

How to enter the unlock codes for CAN-logger

and CAN-snooper

-

Tips for program operation

-

How to associate *.CLC and *.CLD files

with the CAN Logger Utility

-

Command line arguments ,

Batch operation

-

Internals

-

File formats

-

Storage Media

-

Power Supply

-

Legal Terms

-

Latest Revisions

Further information:

Hint: If you use a browser like Firefox, and open the help system from the

utility, this document will automtically be scrolled to the right position.

The same was possible with IE6. But with IE7, this didn't work anymore. Now

it's your decision which browser to use...

Note: If you received this document as a Word- or Adobe Actobat file (pdf)

on a CD-ROM, you will possibly read an outdated 'copy' in this moment. The

guaranteed latest revision is only the documentation in HTML format, which

can be found in the subdirectory \help in the CAN Logger Configuration Utility

! To make sure you are studying the latest version of this document, download

the CAN Logger Utility from the

MKT website,

install it, and read the manual in HTML-form with your favourite browser.

(Hint: With a good HTML browser like Firefox, these pages can also

be printed nicely, with properly formatted page borders )

The CAN-Logger/Snooper is an extra software feature in certain terminals

by MKT Systemtechnik or their resellers. A special firmware is needed to

use the features described in this document, and the terminal must have a

CF- or SD- memory card drive, because the storage medium for the logged data

is a Flash memory card with DOS-compatible file system (FAT16, for MKT-View III/IV also FAT32).

At the time of this writing, the CAN-Logger/Snooper was supported by the

following devices (there may be more than listed below) :

-

MKT-VIEW "plus" with 40 MHz clock, CompactFlash card interface (CF), and

a special firmware (art11089.hex) .

Note: In this firmware, the CAN Snooper and CAN Logger functions must be

enabled by entering a special unlock code. If you want to use one of these

functions but haven't unlocked it yet, please contact the

manufacturer. Only if you ordered the terminal

with this functions already unlocked, you don't need to go through the unlock

procedure.

- MKT-VIEW "II" with ARM-CPU, 72 MHz clock, 4.32 TFT, SD card, firmware #11314.

- MKT-VIEW "III" with ARM-Cortex M3, 96 MHz clock, 4.3" TFT, SD card, firmware #11392.

- MKT-VIEW "IV" with ARM-Cortex M4, 200 MHz clock, 7.0" TFT, SD card, firmware #11532.

In all devices listed above, the CAN logger feature must be unlocked before use.

Devices not listed here can be found in MKT's Device Feature Matrix (external link).

Some definitions of terms which are frequently used throughout this document,

to make sure we know what we are talking about..

-

The CAN-Logger

-

is a piece of hard- and firmware inside the programmable terminal. It writes

the received CAN traffic to a disk file, message-by-message. To reduce the

file size, the CAN identifiers of the logged messages can be selected (from

a CANdb file or "manually").

-

normal "terminal" function remains active in CAN Logger mode

(with reduced performance = lower page update rate if bus load is high)

-

high-resolution timestamp for received messages

-

no display from the CAN logger, it works silently in the background

-

logfile must be analyzed on a windows PC later

-

limited message rate due to memory card hardware restrictions (see chapter

"Limitations")

-

-

The CAN-Snooper

-

is a subroutine in the CAN-logger-firmware. When activated, it works like

a simple CAN analyzer utility to monitor "unknown" CAN

traffic. Received CAN messages are displayed on the terminal's screen.

You don't need a PC to use the CAN-Snooper. The CAN-Snooper is a part of

the firmware in all display terminals which also have the CAN-Logger

functionality. There is no CAN-Snooper without CAN-Logger, and there is

no CAN-Logger without CAN-Snooper - except for the possibility that one of

these functions is unlocked while the other is not ! A more

detailed

description of the CAN-Snooper-mode can be found in the description of

the programmable terminal, but not in this document (this link only works

if you installed the tool in the default directory). This document

only describes the CAN-Logger.

-

-

The CAN-Logger-Configuration / File-Conversion Tool (abbrev'd "CAN

logger utility")

-

is a PC program which helps you to configure the CAN logger, and to convert

the logged data into a format which can be loaded in your analysis program.

The CAN logger utility is *not* a CAN-Logger itself, but it...

-

can read CANdb-files so you can select the

signals which you want to log,

-

lets you modify the logger settings, like

trigger mode, FIFO settings, file size limits, recording interval and more,

-

converts the logfile which is produced

by the CAN logger into some format which can be post-processed with other

programs, like spreadsheets, data visualization tools, statistic evaluation

programs, etc etc.

-

In principle you can use the CAN logger without the CAN logger utility.

You can instead write the CAN logger configuration file yourself (with a

text editor) and write your own import routine for the logfiles (with a

programming language of your choice). If you really consider this, look into

the "file formats" section in the appendix of

this document.

The next chapters provide detailed information about the operation of the

CAN-Logger Configuration and File Conversion Tool. More information about

Display Terminals with CAN-Logger can be found in the manual of the

terminals itself or in the help system of the terminal programming tool.

The description of the programmable terminal is beyond the scope of

this document ! The basic usage of the CAN

logger is briefly explained in a later chapter.

If you have installed the terminal programming tool in its default

directory, you can follow this link to the

description of some interpreter commands, which give you "extended" control

over the CAN logger. For normal applications, you don't need to control the

logger via interpreter commands. The only exceptions are the commands

power=1 (to inform the terminal that the power

supply is safe now, so files may be written) and

power=0 (to indicate that the power supply is

not safe anymore, and that ALL files with write-access must be closed

IMMEDIATELY). More information is in the help system of the terminal programming

tool.

back to top

This chapter explains how to use the CAN Logger Configuration Utility. Producing

a logger configuration file is usually the first step. The

usage of the CAN logger itself is explained

in a later chapter, also how to convert

logfiles will be described later.

The simplest but most ineffective way to start the CAN Logger Configuration

/ File Conversion Utility is to double-click its icon on the desktop, or

in the task bar. It is easier (for every-day use) to associate the file

extensions "CLC" (CAN Logger Configuration) and "CLD" (CAN Logger Data) with

the utility. A detailed how-to can be found in the

appendix.

If you double-click on a CAN logger configuration file to start the utility,

it automatically switches to the Logger Configuration tab.

If you double-click on a CAN logfile (*.cld), the utility automatically switches

to the File Converter tab.

To convert logfiles automatically, the program can be invoked with a

command line (use the \bm switch to enter

"batch mode").

When launching the utility for the first time (after installation), the program

will ask for the target hardware. This is necessary (since February 2008),

because some features and array sizes depend on the target. For example,

the "MKT-View I" (terminal with C167 CPU) has less trigger signals than a

logger built inside the newer "MKT-View II" (terminals with ARM-7 CPU) .

The following dialog allows you to select the target hardware (its appearance

may have changed since the time this document was written) :

This screen will also appear when you create a new logger configuration,

with the option to restore everything to the default values.

The properties of the used hardware can be checked in the tabsheet "Setup",

on the "Options" panel. Some of the hardware/firmware properties of the selected

device are displayed on this panel, for example:

When changing the logger device family, beware that they are not 100% compatible.

For example, the CAN logger inside the "MKT-View I" can filter out a maximum

of 48 different CAN messages from the stream, while the "MKT-View II" supports

a maximum of 128 (or even more). So when switching the device family from

"MKT-View II" to "MKT-View I", some message- and/or signal definitions may

get lost.

Because the CAN logger was primarily intended to log

CAN-SIGNALS(*), you must select

these signals on a special tab of the utility:

(screenshot CANdb tab)

On the CANdb tab, you can

-

Select messages or signals from CANdb files (which can be loaded via the

File menu)

-

Add or remove signals from the list of "logged" signals

-

Rearrange the sequenze of logged signals (the buttons with blue arrows mean

"move up" / "move down")

-

See some information about a logged signal, including the CAN-ID and some

mapping parameters

To import ("load") a CANdb file, use the file menu. If you have used a certain

CANdb file earlier, you will find it in the "Most recent CANdb file" list

- which is quite handy because this way you don't have to remember the full

path name, and it may save a dozen mouseclicks in the file selector box.

To select signals from a loaded CANdb file, you can use..

-

a tree view (as shown in the screenshot)

-

a table view (which contains ALL information about the loaded signals)

-

a group of three lists (NODES, MESSAGES, SIGNALS)

To copy a signal from the tree

view, you can drag it with the mouse and drop it into the list of

logged signals. The same is possible with entire messages (containing multiple

signals), nodes (containing multiple messages), or CAN buses (containing

multiple nodes). You may get a warning if duplicate signal names are already

present in the list of logged signals (in the right part of the window).

Avoid duplicate signal names in your CAN databases whereever possible.

Alternatively, you can select an item in the table view and then

click the "Add signal(s) to list" button.

The list of logged signals will be saved as part of the logger configuration

file. The CANdb file will never be modified because the CAN logger configuration

utility is not a CANdb-editor !

You can use up to four of the logged signals as

trigger signals.

-

(*)footnote:

-

Apart from selecting logged signals from a CANdb file, it

is possible to..

To simplify the selection of signals from large databases, there is a

search function for signal names. You can enter a search pattern

in the edit field close to the "Search"-button, and press ENTER after that

(or click the search button). The search pattern may contain the following

wildcard characters:

-

? Placeholder for "any single character (letter or digit)

-

* Placeholder for a whole group of characters. Must not be used at

the 1st position in the string !

Search pattern examples:

-

Thermo searches all signals named "Thermo", in all messages, on all CAN buses,

sent by any node in the network.

-

A* searches all signals beginning with 'A'

-

?bc* searches all signals with 2nd letter = 'b', 3rd letter = 'c', and an

unknown number of letters afterwards

The properties of any logged signal can be displayed in the "Signal Info"

box. It is in the lower right corner of the signal definition tab. The contents

of this editor-like window may look like this:

| Display (example) |

Explanation |

| PrintedChars |

Signal name |

| id=0x0000007B |

CAN id (+ explanation of the most significant bits 31..29 if set) |

| node="Terminal" |

name of the sending node |

| msg="MuxedMsg" |

name of message containing this signal |

| mapping=(8,8,I,U) |

mapping info: position of LSBit, number of data bits,

byte order: Intel/Motorola,

data type: Signed/Unsigned/Float/Double |

| MuxVal=#0, MuxMap=(0,8,I) |

Only if multiplexed : multiplexor value, multiplexor mapping (see above) |

To see the properties of the logged signal, select it in the list of logged

signals.

Additionally, you can check the CAN message layout in graphical form as explained

in the next chapter .

The layout of a logged CAN message can be displayed in graphical form. This

may be handy when problems with the interpretation of different bit-counting

schemes occurr (for example, "Intel-format", "Motorola forward", "Motorola

backwards" and other oddities).

The graphic shown on the left shows an example of a CAN-message which carries

various signals. The currently selected signal is marked with a bold arrow,

and its name is displayed at the bottom of the window. The arrow always points

from the least significant bit (LSB at the end) to the most significant bit

(MSB at the arrow head).

The bit numbers within a data byte are listed at the top of the display.

Please note that -as usually for binary numbers- the most significant databit

is on the left side; the numbers for 8 bits within a byte always runs from

0 (=LSB, right) to 7 (=MSB, left).

Within the 64 bit of a CAN data field, the bit count runs as shown in the

diagram: The first byte [0] containts bits 7 to 0; the last byte [7] contains

bits 63 to 56. It doesn't matter if the CAN message contains signals in Motorola-

oder/and Intel-Format ! (Caution, some CANdb-editors count bits in a different

fashion, but of course this must not change the physical position of a bit

within the CAN frame).

If the selected signal is multiplexed (as shown here in the example), not

only the signal's data bits, but also the multiplexer for

this signal will be shown (using the same colour, but hatched). The values

of the multiplexer-bits will also be displayed (since the multiplexer value

is a constant which identifies this signal).

-

Note:

-

The multiplexer/multiplexor is also called "mode signal" in other

documents, but this name is rather meaningless so we avoid it.

To select other signals in the displayed message, click into the diagram

with the left mouse button.

Contents

This tab of the Logger Configuration Tool contains a list of the CAN messages

which shall be logged (and some other specialities too).

The lower part of this tab contains a table for "other" logged values, which

will be explained in one of the next chapters.

But first look at the upper table. It contains a list of all

messages which shall be logged.

There is one row in this table for every CAN-message. The

columns in this table are:

-

Nr

This index references the message. It runs from zero to the maximum number

of logged messages.

-

Bus

1 = "Message shall be received from Bus 1 (the first CAN interface)"

2 = "Message shall be received from Bus 2 (the second CAN interface, if

available)"

-

CAN-ID

CAN message identifier in hexadecimal notation. "0x" is the prefix for a

hex number. 11-bit ID's contain three hex digits, 29-bit-ID's eight digits.

-

Message Name

Usually copied from the CANdb-file, in the moment when you added CAN signal(s)

as explained in the previous chapter. For self-defined CAN messages, you

may type short descriptive names, without space characters and other special

characters (only letters and underscores).

-

Sender (Node)

Identifies the sender (the sending "node") of this message. Remember, one

node can send more than one message. Like the message name, this name

originates from the CANdb-file.

-

Intv.-Limit (write-interval

limit)

In this column you can define a message-specific limitation for the write interval

in the logger. For example, a message may be transmitted on the CAN bus

every millisecond, but you only want the logger to write this message

to the memory card every 200 milliseconds. In that case, type "200" into the

Interval-Limit column for this particular message.

Zero means "there is no individual writing interval limit for this

message".

Note: There is also a common write-interval limit for

all messages

(and for logging 'other' data) on the logger configuration tab.

Usually this table will be filled automatically when you

select signals for logging. To add entries

manually (because you have no CANdb file to select signals from), look

here.

Contents

Switch to the "Logger Configuration" tab of the utility. You will see the

current settings in several edit fields, check boxes, combo lists etc. Modify

them for your needs and save the modified configuration (the tool will ask

you upon exit if you want to save the changes, if any).

(screenshot "logger configuration" tab)

The controls on this tab are:

-

Info string

A string of up to 40 characters which can be displayed on the terminal screen,

using the interpreter function "logger.info" .

The upper part of the panel titled "What shall be logged ?" contains three radio buttons (only ONE option can

be selected at a time) :

-

Only the selected messages/signals

The logger only writes the signals into the logfile, which you selected on

the CANdb (or "No CANdb") tab.

-

All signals received by the application

The logger only writes those signals into the logfile, which are received

by the terminal application. The advantage is, you don't

have to produce an extra configuration for every new application of the terminal.

Instead, you log all messages which are handled (received) by the terminal.

-

Receive

and log ALL CAN messages

Useful to analyze the complete CAN bus traffic. This only makes sense if

you export a message list later, not a signal list !

Caution #1 : This option cannot be used together with the option "Limit write

interval for messages" ! Explanation:

see appendix.

Caution #2 : As a matter of course, CAN logfiles can only be converted (decoded)

into physical signals, if the required signal decoding- and scaling information

is available to the logfile converter ! Setting the option "Receive and log

ALL CAN messages" alone (without adding the required signal definitions from

the CAN database) is not sufficient to export decoded signals (not messages)

later. Also see the notes on the logfile converter, option

"Ignore Signal Definitions

from Logfile, use currently loaded signal definitions instead" .

The lower part of the "What shall be logged ?" panel allows to select some other data

(which are not related with normal CAN messages):

Group "Options":

-

Use logfile as circular FIFO, overwrite old data

If this option is set, the opened logfile will work like a FIFO buffer, which

wraps to the start of the file when the maximum file- or disk-space is exceeded.

In other words, if the logfile is "full", the writing-position will jump

back to the begin of the file, and the oldest entries are overwritten. When

the logfile is closed, only the "newest" data are in it - how many, depends

on the maximum file- or disk size.

If this option is not set, old data in the logfile are

not overwritten. Instead, when the file size is reached,

a NEW logfile will be created as explained below (under "maximum size of

a single logfile").

Note: This has not got anything to do with the

pretrigger . The pretrigger memory is always a

RAM buffer, to avoid unnecessary wear of the FLASH memory card, as long as

no "interesting" data are received !

-

Use a new logfile on startup

If this option is set, the logger will use a new filename (with incremented

index) on system start. In other words, a new file for each time you turn

the power on.

Otherwise the logger firmware will try to re-open an already existing file

on system start, and append new data to that file. This option is usually

combined with the option "use file as FIFO". Please note that high-resolution

time channels in the logfile may be not monotonously rising

without this option, as explained here

.

-

Use a new filename for each trigger event

Similar as above. If this option is selected, the logger will use a new filename

whenever the trigger switches from "OFF" to "ON".

Without this option, multiple trigger cycles (trigger ON -> trigger OFF

-> trigger ON) will be recorded in a single file.

-

Keep logfile open

With this option, a logfile will be kept open even if the trigger stops a

recording. This is a bit faster, especially when combined with the pretrigger

option.

Without this option, the logfile will be closed immediately if the trigger

stops a recording, and re-opened when restarted. Use this option if the logger

will be mostly "not triggered", because it reduces the risk of data loss

if the power breaks down by accident (see notes on the

power supply ).

-

Use password and encryption

You may encrypt the logger configuration file and the header section of the

logfile to protect the CAN configuration data. Some user's were not happy

about the ASCII files. If a password is used, the letters and digits in these

files will be scrambled.

Other options..

- Maximum size of a single logfile

A value of zero means "unlimited file size" (only limited by the capacity

of the memory card). Non-zero means the maximum size of a single logfile

shall be limited - usually to a few Megabytes. If the filesize is reached,

the behaviour of the logger depends on the option "Use logfile as circular

FIFO" (explained above). Without this option, the current logfile is

closed and a new file with a different name (increased sequence number in

the last two letters of the filename, for example canlog00.cld, canlog01.cld,

canlog02.cld). This is helpful when you only need to copy a part of the logged

data to your PC. A 500-MByte-monster takes a some time for copying, even

with a fast memory card reader on the USB port - and even longer if you

want to send it to someone via email for examination.

- Limit write interval for messages (and other data)

If you already know that you don't need millisecond-resolution for the logged

data before starting a logging session, limit the write interval

for messages here (in the logger configuration). This will reduce the size

on the flash memory card, and reduce the CPU load of the CAN logger itself,

and will make the conversion of the logfiles into some other formats faster.

See also: write interval of

the CAN logfile converter.

The same parameter is also used as the recording interval (inverse of the sampling rate)

for 'other data', for example

calculated numeric expressions

or logged script variables.

Notes:

- This option has no effect on CAN messages when used together

with the option "Receive and log ALL CAN message identifiers" ! Reason / explanation:

see appendix.

- There is also an individual

write-interval-limiter for certain CAN messages on the "Messages" tab.

Note: The trigger conditions and

trigger options are configured on other

tabsheets !

The CAN logger is controlled by a state machine which can be checked with

the function logger.state (if the CAN logger is part of a

programmable terminal):

The logger states

are:

Stopped

(or "off")

-

The logger (!) is passive and does not consume significant CPU power

-

Messages are not placed in the log buffer

-

The logfiles on the flash memory card are closed

-

The trigger condition are not monitored (because messages are not handled

in this state). This saves a large amount of CPU power !

Engaged

-

The logger function is active and analyses all received CAN messages. The

CPU load is already higher than in the stopped state.

-

Logfiles on the flash memory card are already opened, and -if the file is

used as a giant FIFO- new entries may already be written to the file.

-

The trigger conditions are permanently monitored to detect a possible "start"

condition. If a START condition is detected, the logger switches from

enaged to triggered.

Triggered

-

The logger function is active and analyses all received CAN messages. The

CPU load is even higher than in the engaged state.

-

Received messages are written from a RAM buffer to the memory card.

-

The trigger conditions are still monitored to detect a possible "stop" condition.

If a STOP condition is detected while the START condition if

false, the logger switches from triggered to

engaged state (but not to stopped !).

-

Note: the post-trigger phase is almost the same

as the 'triggered'. The only difference is the value returned by the

logger.state function of the

interpreter.

The initial logger state after power-on can is defined on the

Trigger Option tab ("triggered by default"

etc).

The transitions between the logger states are either initiated

by the logger itself, depending on the trigger conditions, or with an interpreter

command. A complete list of logger control commands is in the

manual of the terminal programming

tool. Here just a few of those commands :

-

logger.run

-

Activates the CAN logger, but does not necessarily trigger it

(depending on the configuration). Switches from stopped to

engaged, but not from triggered to engaged. If the firmware

refuses to switch into the engaged state, there may be something wrong with

the memory card.

-

logger.stop

-

Stops the CAN logger. The logfile on the memory card is closed, so you can

safely remove the card. No popup window appears (in contrast to the 'card.remove'

command. In the stopped state, the trigger condition is not permanently checked

in every received CAN message, which saves a large amount of CPU power !

-

logger.trigger(X)

-

Triggers a recording (X=1) or clears the trigger flag (X=0). Does not close

the logfile. Intention: Manual trigger or trigger by the user-programmable

terminal application. Examples:

logger.trigger(1) : rem Start recording to the CF card

logger.trigger=1 : rem Same effect as above, only different

syntax

logger.trigger=0 : rem Stop recording, but keep buffering received

frames

If the firmware refuses to write data to the memory card, the reason may

be power=0 (power-good flag not set).

Note about "logger.run" vs "logger.trigger":

Setting the trigger (=begin writing to the logfile) with this command

automatically includes activating the logger (logger.run). But,

if the logger was not running when executing the trigger-command, there will

be nothing in the pretrigger-buffer.

So, if you need

pretrigger-data, activate the

logger before triggering it !

-

logger.state

-

Returns the current state of the CAN logger as a numeric value. Possible

results :

0 = "stopped" (file not open, or buffer not filled in interrupt, possibly

a problem with the memory card)

1 = "engaged" (file open, ISR active, but not triggered yet)

2 = "triggered" (file open, ISR active, AND "triggered" )

3 = "post-trigger" (after "triggered"). Only occurrs if the

post-trigger time in the logger configuration

is non-zero.

Notes:

-

You don't have to use these interpreter commands to controll the logger's

trigger ! Usually, the logger works silently in the background, and you don't

have to care for it when programming your terminal application. The logger

control commands have only been implemented for 'very special cases', when

the built-in trigger possibilities are not sufficient.

-

There are some other interpreter commands to control the logger, and to check

the memory card, explained in the

manual of the terminal programming

tool. Such commands include: card.insert, card.remove, card.dspace (retrieve

free disk space in kByte)

Pretrigger

You may be interested in the history of the logged signals a short while

*before* the trigger event. This is possible, because the logger records

the most recent message in a RAM buffer even if the logger is not in the

'triggered' state. By setting the pretrigger-field to a value greater than

zero (seconds), a part of the messages in the RAM buffer will be flushed

to the logfile when the trigger start condition becomes TRUE.

Note: Depending on the size of the RAM buffer, and the average message rate

on the CAN bus, the logger firmware may not be able to save as much 'seconds

of pretrigger data' as you want. The buffer capacity which is available for

pretriggering is roughly 3000 messages.

The pretrigger interval is defined on the

'trigger options' tab.

Posttrigger

To record a few seconds *after* the trigger condition became FALSE (and/or

the stop condition became TRUE), set the posttrigger-field to a value greater

than zero (0 means "no post-trigger"). Usually, recording to the logfile

stops 0...10 milliseconds after the trigger is stopped. With the posttrigger

option, you can record some additional seconds. The posttrigger's internal

function is very different from the pretrigger, there is no limitation due

to the RAM buffer size for the posttrigger (the maximum is 327.67 seconds

of post-trigger data).

The posttrigger interval is defined on the

'trigger options' tab.

This chapter only applies to the older "MKT-View I" with 16-bit CPU !

If you are using the "MKT-View II" (with 32-bit CPU), use the

Trigger Condition Grid as explained

in the next chapter instead !

In the MKT-View I, you can use up to four signals as trigger sources. The

trigger condition tab may look like this:

(screenshot "trigger conditions", blue marks explained below)

The components of a trigger definition are:

-

1 = Trigger Signal (source)

-

The list in this combo box contains a list of all possible trigger sources.

If the list is empty: see notes

below.

-

2 = Compare Operator

-

Possible comparisons are: <, >, <=, >=

-

3 = Comparation Value

-

Enter a numeric constant here. The format is the signal's scaled value.

But caution:

Internally, the trigger operates on RAW CAN VALUES. So avoid values which

don't exist on the CAN bus, for example 0.5 if the signal is a one-bit-value

which can only be 0 or 1.

-

4 = Inner boolean combination

-

The two comparations can be logically AND - or OR -combined.

-

5 = Outer boolean combination

-

Defines how the two conditions shall be combined. For example, logging may

start when BOTH conditions are true ("AND"), or when ANY of the conditions

is true ("OR"). If you do not need the second conditional term, set the outer

combination to "--".

Usually, there is a trigger START condition and a trigger STOP condition.

If you don't need a STOP condition, you can use lines 5...8 of the trigger

condition as an additional set of START conditions.

There are four trigger sources, which must be connected to SIGNALS. The combo

boxes are filled with the list of logged CAN SIGNALS. If these

lists are empty,

you must import some logged signals on the CANdb

import tab before you can define the trigger conditions !

Notes:

-

You don't have to use all these trigger conditions. Set unused trigger signals

to "--unused--" in the trigger signal selectors

(1) . If only one trigger condition is used

(like

Thermo1 < 1.1), you don't need the logical combinations.

You don't even need a single trigger condition if you set the initial

trigger state on the logger configuration tab to

"triggered".

-

The logical AND combination returns TRUE if both inputs are

TRUE, and returns FALSE in all other cases. If comparation operators or

comparation values are improperly selected, an AND combination may NEVER

return "TRUE", for example "(X<7) AND (X>8)". The utility tries to

check such conditions and shows a warning if this may happen.

-

The logic OR combination returns TRUE if any of the two inputs

is TRUE, and returns FALSE only if both inputs are FALSE. If comparation

operators or comparation values are improperly selected, an OR combination

may ALWAYS return "TRUE", for example "(X<8) OR (X>7)". The utility

tries to check such conditions and shows a warning if this may happen.

-

If both START- and STOP condition are TRUE at the same time, the logger will

be triggered. If either START nor STOP are TRUE, the

logger state is not changed.

The trigger input works as explained in the following

circuit schematics. The trigger is, of course,

realized with a piece of microcontroller firmware instead of logic gates.

Each of the four trigger input variables (V1...V4) is compared against two

constants (C1...C8). The comparator results can be selected individually

for 'less than' (<), 'less or equal' (<=), 'greater' (>) or 'greater

or equal' (>=) with the comparator output switches CO1...CO2.

In the next stage, the comparator outputs are combined in two stages, each

selectable for logical AND or OR combination. The combined results are labeled

Start and Stop signal in the above diagram. They

are the inputs into a Set/Reset flipflop with the following truth table:

| START |

STOP |

new trigger state |

| 0 |

0 |

NO CHANGE |

| 0 |

1 |

untriggered (engaged) |

| 1 |

0 |

triggered |

| 1 |

1 |

triggered (!) |

Usually, the logger operates in a state-triggered mode (as shown

in the truth table). Alternatively, it can be set to

edge-triggered mode as shown in the

next chapter.

Note that if both START and STOP condition are TRUE (1) at the same time,

the logger will be triggered !

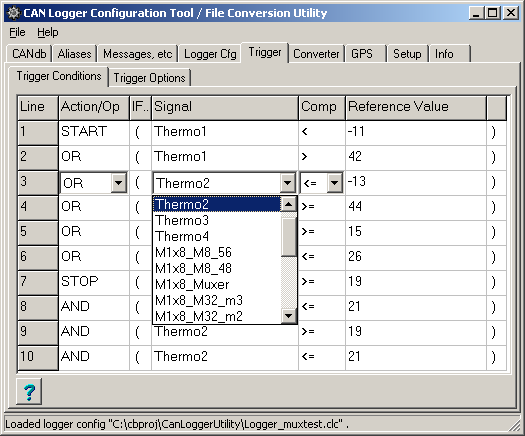

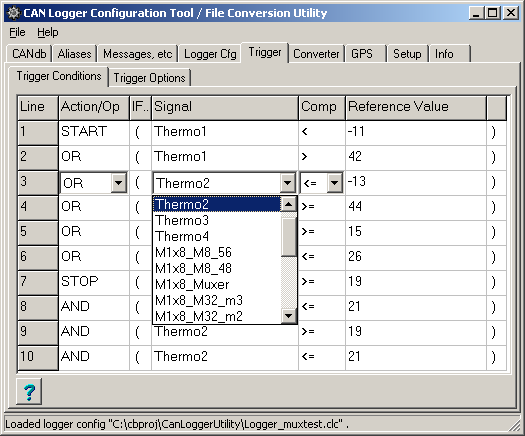

This chapter only applies to the newer "MKT-View II" with 32-bit CPU (ARM-7) !

If you are using the older "MKT-View I" (with 16-bit CPU), use the

Trigger Condition Tab as explained in

the previous chapter instead !

The MKT-View II allows the definition of up to ten (?) trigger signals. Each

of these trigger signals can be used either as START- or as STOP-condition.

In contrast to the older MKT-View I, the trigger signals are defined in a

table ("grid") as shown below.

Note: Before you can select trigger signals, you must import at least one

CANdb file, and select all ignals which shall be logged.

The columns in the trigger definition table are ..

-

Line : line number, running from 1 to 10 if ten different trigger sources

are supported.

-

Action/Op (Action or logic operator)

START : This line is the begin of a new START-conditon

STOP: This line is the begin of a new STOP-conditon

OR : This line contains a sub-expression which will be logically ORed to

the previous line

AND: This line contains a sub-expression which will be logically ANDed to

the previous line

Note:

-

In this trigger definition table, there are no different prioritities for

AND / OR, in contrast to programming languages like "C" and Java. The logical

combination is always evaluated in the sequence of the table (i.e. evaluated

from top to bottom).

-

If there is no STOP condition in the table at all, the logger uses the inverted

START condition as STOP.

-

IF.. : The opening parenthesis in this column marks the begin of a comparison

between the trigger signal and a reference value.

You can read the table like: "START IF ( Thermo1 less than -11 degrees )

OR IF ( Thermo1 greater than +42 degrees celsius)"

-

Signal : Name of the trigger signal (received from the CAN bus).

To select a signal, click into the field to open a combo box. All signals

which can be used as trigger source are listed in the combo, and -possibly-

some other sources which are *not* CAN signals.

-

Comp (Comparator) : Comparison operator, can be either

"<" (less than), "<=" (less or equal), ">" (greater than), ">="

(greater or equal).

In addition (only for MKT-View II with firmware date 2009-01-08 or

later) :

"==" (equal), "!=" (not equal), "&" (bitwise AND, here: used as

bit-test-operation)

-

Reference Value : The trigger signal will be permanently compared with this

value .

(At the time of this writing, the reference value had to be a

constant. This may(!) change in future versions of the MKT-View

II firmware)

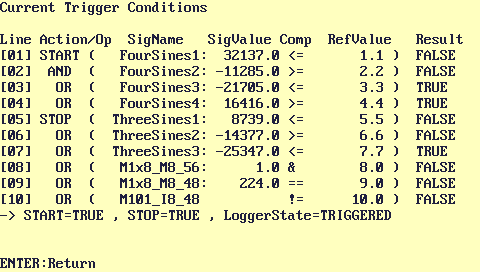

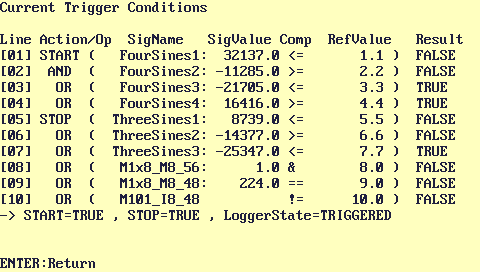

Hint: You can check the actual state of the trigger signals during operation

on the "MKT-View II". To do this, enter the terminal's

system menu, or open the shutdown screen. Select

"CAN-Logger" or "CAN logger config", "Trigger Settings"..."Show Trigger

Conditions". You will see all trigger signals (in the same order as in the

table shown above), along with the signal names, the current signal values

(column "SigValue", if the signal has been received since we started), and

the result of the comparison in each line :

The screen also shows the combined start- and stop conditions, and

the current state of the logger (passive / enaged / triggered / post-trigger

).

< under development ... more coming soon ... ;-) >

The following TRIGGER options can be defined on this tabsheet of the Logger

Configuration Utility :

-

Initial trigger

state

Defines the initial state of the logger's trigger, as described in the chapter

The Trigger State Machine.

When set to "Triggered", logging starts immediately after the terminal is

powered on (as if the trigger condition was "immediately TRUE"). Otherwise,

logging starts when the condition defined on the

trigger condition tab gets TRUE.

-

Pretrigger (seconds)

Define how many seconds of logdata you want to have recorded BEFORE the trigger

event. Note that there may be less than the desired pretrigger size, depending

on the CAN message rate and the size of the internal buffer (approximately

3000 messages can be buffered internally, so don't expect too much pretrigger

data if there are 2000 messages per second in your network !). A value of

zero means "no pre-trigger".

-

Post-trigger

(seconds)

Define how many seconds of logdata shall be written AFTER the trigger stop

condition has been detected. Up to 327 seconds of post-trigger data are possible.

A value of zero means "no post-trigger".

-

trigger on RISING EDGE of start-conditions

Set this checkmark if you to trigger on the rising edge of the trigger

start condition(*). This means, trigger only if the

start condition changes from FALSE to TRUE. If this mark is unchecked, the

CAN logger will operate in state-triggered mode.

-

trigger on FALLING EDGE of start-conditions

Trigger recording if the start condition changes from TRUE

to FALSE . Can be combined with the previous option to trigger on both slopes

(rising+falling).

-

stop on RISING EDGE of stop-conditions

Stop logging if the stop condition changes from FALSE to TRUE . Without this

option, the stop condition works in state-triggered mode.

-

stop on FALLING EDGE of stop-conditions

Stop logging if the stop condition changes from TRUE to FALSE . Can be combined

with the previous option to trigger on both slopes .

-

Pre- and post-trigger phase only (time-limited recording)

Should be used in edge-triggered mode only. The logfile will only consist

of a few seconds of pre-trigger data, and a limited interval of post-trigger

data, but nothing in between. For example, use this option to trigger on

a signal which changes from "low" to "high", and then stays "high" forever,

but you only need a recording of a few seconds before and after the low-high

transition. The number of seconds before the transition is the

pretrigger interval, the recording time

after the transition is the post-trigger

interval.

Below is an example for edge-triggered logging, with a time-limited recoring

consisting of 10 seconds before the trigger (pre-trigger), and 20 seconds

after the trigger (post-trigger) :

(Example for an edge-triggered configuration, with time-limited recording

for each new event)

(*) Note: "Rising" / "Falling" edge applies to the trigger-start-condition

(TRUE/FALSE), not to the physical value of the trigger signal itself ! If

you don't understand this little but important difference, look at the

trigger block diagram again. The trigger signals

are on the left side, the trigger conditions are the outputs labelled "Start"

and "Stop".

You can, if requrired, also log other CAN messages which are not defined

in a CANdb file. You may use this as a makeshift solution if there is no

CANdb file available at all.

The contents of this table were explained in a previous chapter - if you

missed it, click here .

Note: The messages defined this way cannot be 'decoded' into signals ! So

defining your own messages here only makes sense if you want to have a listing

of CAN messages (no signals) and their data in hexadecimal

form. Defining own signals is not possible with this tool - use an external

CANdb editor for that task ! There are some very

nice CANdb editors around, for example by Vector or Kvaser which can be used

to create your own CAN database.

Certain terminals (like "MKT-View") have a built-in NMEA-decoder, which allows

them to decode data from a GPS receiver. If that function is available, the

GPS data can be logged together with the other data. Of course, you need

a suited GPS receiver with an RS-232 interface (often called "GPS mouse")

for this job. Furthermore, if the GPS receiver needs some special initialisation

sequence to start, make sure you configure it correctly (this can be done

with the display program, using the "gps"-commands which are not scope of

this document). Just an example, usually located in the event definitions

on page 0:

gps.baud=9600 : gps.prot="NMEA" :

gps.cfg=1 : rem Init GPS-mouse, 1 Hz

To record GPS data with the CAN logger, set the checkmark "Log data from

GPS receiver" on the logger configuration panel.

This flag will be saved as part of the logger configuration file (logger.clc).

Alternatively, you can turn GPS logging on or off in the terminal's system menu

(select "CAN logger config" ... "Buffer/Mode settings" ... "Record GPS (nav) data",

and set the parameter value to TRUE or FALSE. Don't forget to save the modified

configuration after that ! ).

To define how the GPS data shall be converted into other files later, there

is a special tabsheet named "GPS" in the

CAN logfile converter.

In addition to logging CAN messages, the logger in the MKT-View terminal

may also log some other data. For this purpose, you may enter up to eight

numeric expressions in the table shown below.

These expressions will be evaluated once per write interval (if

there is no write interval specified, once every 100 milliseconds).

The same table is (internally) also used to log script variables, more on that later.

Remember that built-in functions always begin with a lower case letter,

user-defined display variables must begin with an upper-case letter !

More information about numerical expressions can be found in the manual for the

terminal programming tool.

The definition table for numeric expressions is on the lower part of the "Messages, etc" tab of

the CAN logger configuration utility. In the example, the following values

are logged: The first analog input (ain1), the terminal's supply voltage

( sys.vsup, here scaled into Volts), the terminal's internal temperature

(sys.temp, here in degrees Celsius), the current page number (pn), and the

count of "lost" messages (logger.lost). These values will be added in extra

columns of the converted logfile. If no name is specified in the table, the

expressions themselves will be used as column names - which may cause problems

in the exported ASCII file if the expression contains the

column separator character.

The min- and max values are only used for the graphic preview window. The

values actually recorded and exported will *not* be limited to this

range !

Notes: Because evaluating these expressions with the interpreter may be quite

time-consuming, it makes no sense to use sampling intervals below 100

milliseconds. Logging the interpreted results only makes sense if the

output type for the logfile converter

is set to Signals (not Messages !).

Since January 2014, it is possible to log script variables along with the CAN traffic.

To achieve that, ...

- the to-be-logged script variables must be declared (in the script) with the 'logged:' attribute;

- the option add script variables declared as 'logged' must be set on the panel titled 'What shall be logged';

- there must be sufficient space left in the table with 'numeric expressions' shown above

- the sampling rate (inverse of the write interval) must be set to a meaningful and realistic value

After reading the logger configuration file, the device firmware will automatically append the names

of all SCRIPT VARIABLES declared with the 'logged' attribute as 'numeric expressions'

(after those entries which you possibly entered yourself, manually, in that table).

It's not necessary (and not possible!) to enter the names of script variables

in the table shown above - it's enough to declare them as 'logged' in the script sourcecode.

The sampling rate for those script variables is the same as for the other rows in the 'NUMERIC EXPRESSIONS',

defined as write interval (limit) on the Logger Configuration tab.

See also: Script language manual (pdf, online) .

After all logged signals are defined, and the logger configuration -including

the trigger settings- is finished, you must save the CAN Logger Configuration

file (*.CLC) on a Compact Flash Memory Card because this is the only way

to transfer the configuration into the logger hardware. On the memory card

which will be used in the logger later, the configuration file must have

the name LOGGER.CLC because only this file will be read automatically from

the Compact Flash Memory Card when the logger is powered up.

To achieve this almost "automatically", you can set the tool's default directory

on the Settings tab so the logfile will be automatically be

written to the memory card (if you have a suitable

memory card reader / writer installed

in your PC). The next chapter will show you how.

If the configuration has been changed, the program will ask if you want to

save the modified configuration in a file. If you have the memory card in

the drive at that time, click "Yes" and the new configuration will be written

to the memory card without further questions.

On the Settings tab of the logger utility, you can define the

default directories for some frequently used file types :

(screenshot "directories")

Note: On the author's PC, drive "I:\" is the memory card's drive. This will

be different on your PC !

To modify the file- or directory names, you can either type the name in the

edit field or click on the "..." button to its right to open a selection

dialog. The following fields can be modified in the Directories group :

-

CAN log files

-

This is the default directory for logfiles. You may set this to your CompactFlash

card drive, but often the file conversion runs faster if you copy the logfiles

from the memory card to your local harddisk before converting them (especially

if these files are very large !)

-

Logger

config

-

The name and location of the CAN logger configuration file. For your convenience,

select your memory card drive here, and use the filename LOGGER.CFG because

this file will by loaded into the logger automatically during power-up.

-

CANdb files

-

This is the default directory for importing CANdb files

-

Exported

-

This is the directory where the converted files are written to ("exported").

back to top

The CAN Logger can be used in two basic modes:

-

Log 'all received messages', no matter how frequently they are received.

Advantage: Message timing and frame rates can be reconstructed later

Disadvantage: Unpredictable logging capacity in terms of recording time.

Danger of system overload.

-

Log the 'latest received messages' with a limited recording interval.

Advantage: You know how many hours of data can be logged. System overload

is unlikely.

Disadvantage: Cannot see the run of the curve in between the recording

intervals

The messages which shall be logged can be selected with the Logger Configuration

Utility (as already described in another

chapter). The signals which shall be logged may be selected from

a CANdb file. The Logger Configuration Utility produces a configuration file

for the logger, which will be loaded by the logger during initialisation.

The following steps must be performed for a complete configuration / logging

/ analysis - cycle:

-

Produce a logger configuration file as explained

here . This includes selecting what you

want to log , and how to log the data !

-

Copy the logger configuration file to a Compact Flash Memory Card

(or save it directly on the card from the logger

configuration utility)

-

Turn the CAN logger off (obey the proper power-down sequence)

-

Insert the memory card in the logger's CF memory card slot

-

Connect the logger with the CAN bus which you want to analyze

-

Turn the CAN logger on

-

Set "power=1" in your terminal program (via

interpreter, when the supply voltage is REALLY safe).

-

Let the logger log (triggered or untriggered)

-

Set "power=0" if there is the risk that someone

cuts off both supply voltages simultaneously

-

Turn the CAN logger off (obeying the proper power-down sequence !)

-

Remove the memory card from the logger and insert it in your PC's card reader

-

Start the logfile converter as explained

later

-

Load the converted files into an analysis tool of your choice

The logger configuration is saved in a small textfile named

LOGGER.CLC (CLC = Can Logger Configuration), which must

be placed in the root directory of the memory card. Usually this file will

be created and modified by the Logger Tool; in other words the file

LOGGER.CLC is the connection between the tool and the

logger itself. It's usually a one-way-street: The

CAN-Logger-Configuration-Utility writes this file, the CAN-Logger

(hardware) only reads the CLC-file !

While the logger is active, it usually waits for the

trigger condition, and -once triggered-

records the selected messages in a file with the extension CLD (Can Logger

Data). When logging is stopped, the file is closed. When a new trigger condition

occurrs, a new CLD file may be written (the old data are not lost). To remove

the card from the logger, you must either turn the logger off, or invoke

a firmware command to close the logfile. Otherwise you would damage the data

on the card (directory or FAT). If this happens by mistake, you must run

the program SCANDISK to repair the card's file system.

The logged file(s) can be converted with the logger tool into various other

file formats, which will contain the decoded signal values (not the raw CAN

messages). These files can then be loaded into other programs like

Excel™,

DIAdem™, and some other programs too.

Alternatively, the logfiles can be converted into

Vector™ ASCII CAN logfiles, which -for

example- can be played back into the CAN network in the laboratory for testing

purposes. MKT's own CAN-bus-tester can do this too.

The supply voltage of first hardware versions of the MKT view terminal (I,

not II) was specified 9 to 36 Volts,

for both "switched" and "standby" voltage. As mentioned in the hardware manual,

the standby voltage is required to shut the terminal down properly, including

closing all open files which very important to keep the CF memory card's

directory structure and file allocation table in order.

Caution: While data are been read from or written to the memory

card,

it must not be removed from the device, and the device must not be turned

off.

On some devices (for example, terminals with SD-/MMC-cards)

a red LED near the card slot signals this state.

Ignoring this rule may damage data on the card.

Backup your data wherever possible !

MKT Systemtechnik will not accept responsibility for any data loss

or loss directly or indirectly caused by data loss. |

A problem arose when the terminal was used in passenger cars with 12 Volt

power supply, when both (switched + standby) voltages were fed by the same

battery. When starting the engine, the battery voltage dropped to 6 Volts

which is not sufficient for the terminal. When, in this condition, a logfile

was open, the data on the card were corrupted (destruction of FAT and/or

wrong directory entries).

Note: If there was an illegal / unexpected power shutdown, the terminal will

show the following message when turned on again:

SOS - Device has NOT been shut down

properly, maybe supply voltages

are connected in parallel ?

THIS MAY DAMAGE THE MEMORY CARD !

USE MS-"SCANDISK"(*) TO REPAIR IT ! |

(*) The program SCANDISK was used under Win 98.

Under Win XP, it doesn't exist any longer;

use CHKDSK or a similar utility in that case.

To relax this hardware problem via software, the flash memory card is disabled

for any WRITE-access until your terminal application sets the "power good"

flag. This can be done with the following interpreter command:

-

power=1

-

This command means "The power supply is safe now, there is no risk of losing

both supply voltages at the same time".

You may use it in an event definition, triggered -for example- by a comparison

of the engine revolution speed. If the motor runs at 1000 RPM or more, set

power=1 . If you cannot access the motor's RPM value via CAN, use a

hotkey to set "power=1" - with the disadvantage that it will be the operator's

responsibility to press the button only AFTER starting the engine.

-

power=0

-

This command means "The power supply is unsafe now, there is the risk that

both supply voltages will fail at the same time".

You may use it in an event definition, triggered -for example- if the motor

runs at 500 RPM or less.

Setting "power=0" disables write accesses to the CF memory card. This will

cause the terminal to close all files which were opened for writing, including

the logfile, etc.

For testing or 'diagnostic' purposes, you can read the state of the power-good

flag like an ordinary variable. But remember, it is YOUR task to keep this

flag up-to-date.

The default state of 'power' is zero, which means power is unsafe, and writing

to the CF memory card is impossible. In a future redesign of the terminal

hardware, this may change. If the terminal runs properly at 6 Volts (or less),

we may modify the firmware so the power-good flag will be '1' by default.

In the sample terminal application "LogDemo1.cvt" (distributed with the terminal

programming tool), you will find an example for the usage of the power-good

flag. In the simple example, the user is asked to "press any key" as soon

as he thinks the power is safe, and to press the F1 key later before turning

the engine off. As explained above, you may replace this with a more

sophisticated solution, using the engine's revolution speed to set power=0

or power=1.

The problems mentioned above do not apply to the

MKT-View II (with ARM-CPU, available since

2008). The MKT-View II has an internal backup-capacitor, which can provide

the power for a few seconds after removal of the external supply voltage.

So the CPU can savely power down the memory card, even if all external voltages

are removed. For compatibility reasons, the power-flag still exists

in the MKT-View II, but it is automatically set to TRUE as soon as the backup

capacitor is fully charged (which takes a few seconds after power-on).

back to top

Note: This document describes a work in progress. The

finally released version may look different !

To convert a logfile from the CAN logger into some format, use the "File

Converter" tab of the CAN logger utility. If you double-click on a *.cld

file (CAN Logger Data file), this tab will be opened automatically.

The list on the left side contains the names of all files which shall be

converted. With the Select files button, you can add more files

to the list. Alternatively, you can add logfiles (*.cld) from an explorer

window via drag- and drop.

The fields in the Destination box describe the format of the

output file. The settings in this box depend on the program used for

post-processing (for example: spreadsheets, data visualization tools, statistic

evaluation programs). You will only have to adjust these settings once, because

they are saved permanently in a special configuration file (not in the

logger configuration file !).

To start the conversion, click on the Go! button. The name of

destination file will be automatically produced by the tool, matching the

input file but using a different extension; it is displayed on the bottom

of the File Converter tab.

The conversion parameters are:

-

Output

Type

-

Signals: Write signals, not CAN messages into the output files.

All signals which are contained in the logfile are decoded, the results are

written into the output file.

Messages: Do not decode the messages from the logfile, instead

write the CAN message frames in hexadecimal form (one frame per text line).

Though this mode may sound exotic : it fulfils the function of a true CAN

LOGGER !

-

Output file format

-

An awful number of different output file formats had to be implemented for

various users, here just a few...

-

-

Text

-

A plain textfile ("ASCII") which can be viewed with any text editor, or imported

into many spreadsheet programs.

You must define the separator characters for the text ouput format in a few

other edit fields, see below.

-

CSV, international

-

Comma Separated Values. Can be imported into many spreadsheets on a PC with

an english windows installation

-

"CSV", german

-

This 'nationale' CSV-variety can use a comma instead of the decimal point.

Some (german) programs then use the semicolon as a coloumn separator, others

(like the german version of Open Office) use the comma for both (!), and

put the characters of a fields in double quotes. In contrast to the

"international" CSV, both column- and decimal-separator can be selected

individually for this format, so you can produce "comma-separated values"

with this format as well as "semicolon-separated values".

-

DIAdem, ASCII

-

Produce a separate "header" file (*.dat!) and a "data" file (*.asc) to be

loaded into DIAdem. Never tested because our old copy of DIAdem crashed whenever

trying to make a graphic plot from the logged data (-> DIAdem V7 showed

a steaming coffe cup but no response to any user action, not even

CTRL-ALT-DELETE).

-

DIAdem, INT32

-

Produce a separate "header" file (*.dat!) and a "data" file (*.i32). May

load a bit faster into DIAdem but never tested successfully.

-

DIAdem, REAL64

-

Similar as above, but here the data are saved in binary files as 64-bit floating

point numbers. This format avoids some problems with scaled time channels,

because floating-point numbers offer the best resolution and the largest

possible value range.

-

Stiegele MDF (c) STIEGELE Datensysteme : MDF = Measure Description

File.

-

This format also uses separate header- and data files. The header file (*.mdf)

contains all informations required for post-processing; the data file (*.dta)

contains the measured data. Note: MKT's Logfile-to-MDF-Converter only supports

data types 'float', 'double', and 'ymdhms' for this file format.

-

VECTOR-MDF (*.dat)

-

This is VECTOR's MDF format. It may (or may not) be compatible with recent

versions of ETAS / INCA / MDA but we could not validate this. Because of

trouble with ETAS MDA V4.0 (files didn't load even though Vector's MDF Vaildator

showed no problems), the time channel now starts at zero at the begin of

each measurement.

-

VECTOR-compatible, ASCII (CAN message log)

-

Similar like the ASCII logfile format used by Vector's CANoe / CANalyzer,

but does not support all features because we had no detailed specifications

about this format. In contrast to the Vector tools, the identifier is always

noted in hexadecimal form, also the message data bytes.

Since 2010-05-26, the converter appends an 'x'-suffix to 29-bit identifiers,

for compatibility with Vector's CANoe.

-

ETAS ASCII ("ETASAsciiItemFile")

-

Added 2011-02-17, when certain files (in Vector's MDF format)

didn't load properly in ETAS MDA. The ASCII format has the big advantage

that it's not a binary file format (in contrast to MDF / ".dat") so you can

easily examine these files with a text editor. Hint: Use a good

text editor like Notepad++, set

the tab size to 20 characters or more (so the columns are properly aligned

on the screen), and you have a quick tabular display for your ASCII data

files. The column separator is always the TAB character (0x09).

-

-

Column separator (field

separator)

-

Select space, tab, comma or

semicolon as column separator. Only enabled for output file

format = text. Not adjustable for most other output file formats (especially

not for binary formats).

-

Decimal separator

-

Select period(.) or comma(,) . Even German users

should use the period character if they are working for international companies,

and have to mail their results across the pond !

-

Time Column

-

Select if the output file shall have a time column, and which format shall

be used (where applicable). For certain output file formats, the format of

the time columns cannot be modified (like DIAdem where the time colum, if

selected, will always be something like year+month+day+hour+minute+second,

which is not very accurate because the seconds can only be integer

values. See notes on diadem for details).

For text file output, the following time column formats are possible:

YYYY-MM-DD hh:mm:ss = ISO8601-formatted date and time

Milliseconds = only the "high-resolution" timestamp (which starts at zero

when the device is powered on). Integer value !

Seconds = Similar as above, scaled into seconds, as a floating point value

.

Note: If multiple test runs are recorded in a single file, during which the

device is turned off and on again, the time-channels formatted as

seconds or milliseconds will not be monotonously

rising within that logfile ! If your post-processing program cannot

handle this, use the option new filename

on startup in your logger configuration !

-

Write

Interval (for logfile conversion)

-

Can be used to reduce the size of the output file. If, for example, you only

need a 1-second raster for the exported lines instead of a 10-millisecond-raster

in the logfile, you can reduce the data size, set this write

interval to 1.0 before starting the conversion.

If you know before your logging session, that you don't need

millisecond-resolution for the logged data, limit the

write interval for messages in

the logger configuration. This will reduce the size on the flash memory

card, and reduce the CPU load of the CAN logger itself.

-

back to top

Additional (less frequently used) settings for the CAN logfile converter

can be defined on the tabsheet "Converter" ... "Converter Options" :

-

Invalid Signal Value

-

Some analysis tools need a certain value for "invalid signals". An invalid

signal is, for example, a signal which has not been received yet. The value

from this edit field will be copied into the output file as long as a signal

is invalid. Once a signal has been received, it is and remains valid.

If the output file format is a text file, you may enter any string here.

For all other file formats, this field has either no function (because the

invalid signal value is fixed), or must be a numeric value like

"-99999999".

-

Signal Values: Raw or Scaled ?

-

Has been used during development. Should be set to "Scaled" usually.

Raw: Do not convert the raw CAN value into the physical value

(do not apply offset and factor)

Scaled: Convert the raw CAN values into physical values, using

the signal's conversion parameters offset and factor

-

Headlines

-

Defines, if and how many header lines shall be written

before the actual data ("values"). Only available when converting into TEXT

files (*.txt or *.csv). The headlines contain:

- First line: Contains the column names (often: signal names) which is helpful

when post-processing the file with a spreadsheet program

- Second: If enabled, this line contains the physical units for each

data column.

- Third: Rarely used; if enabled this line contains the

logger-info-string (read from the logfile

!)

If "Headlines" is set to zero, none of these lines will be written into the

output file. For export file types like "DIAdem" and "Vector", this parameter

has no effect.

-

"Ignore signal definitions

from logfile, use currently loaded signals instead"

-

You can try to use this option to convert logfiles into signals, if the logfile

itself does not contain any (or not the right) signal definitions ... for

example, because you have only set the option

"Record all identifiers" in

the CAN logger configuration, without selecting any CAN signals from a CANdb

file (*). Be very careful with this option, and make sure you picked the

right CANdb file, which matches the CAN messages in the recording. Otherwise

you may end up with an empty (at best) output file, or an output file containing

only 'garbage'.

(*) The reason for missing CAN signal definitions in the logged file

(*.cld) may be a mistake of the person who prepared the CAN logger configuration

(logger.clc), but this may also be done deliberately by "someone" to

keep the CAN signal definitions secret. Whether a CAN logger configuration

(or a CAN logfile) contains signal definitions or not can be easily checked

with a text editor: If the file header only contains two "dummy definitions"

like the the following ...

Msg00: id=0xFFFFFFFF,mn="",nn="",wi=0

Sig00:

id=0xFFFFFFFF,sn="",ty=S,un="",fa=1,of=0,mi=0,ma=0,sb=0,nb=0,bo=M

.... then the logfile cannot be converted into signals (only into

a CAN message dump) without the option "Ignore signal definitions from the

logfile" - and of course, only if you have access to the CANdb files ! Details

about the file formats can be found in the appendix.

When using this option, proceed as follows:

-

before starting the converter, load the CANdb files which match

the recorded CAN-messages.

-

On the tabsheet "CANdb", select those signals which shall be written into

the output file - the same way as creating a new CAN logger configuration

(in fact, the signal definitions will temporarily overwrite definitions loaded

from LOGGER.CLC).

Only the N signals listed in the right part of the CANdb

tab will be converted (" N logged signals in x messages

").

-

After that, switch back to the tabsheet "Converter".

-

Make sure the Converter Option "Ignore Signal Definitions in

Logfile" is set.

-

Select all CAN logfiles (*.cld) which are compatible with the signal definitions

loaded above.

Remember the file selector trick to select multiple files at once (shift-

or control key pressed during mouse click)...

-

Start the conversion .

You can avoid this complexity by always adding all required CAN signal

definitions to the CAN logger configuration. The CAN logger itself will copy

these definitions to the logfile then, so the converter "automatically" knows

how to decode the signals. But in some conditions, or to keep the signal

definitions 'secret', you can use this converter option (along with the logger

option "record ALL identifiers"). Neither the logger configuration file,

nor the logfile need to contain any information about how to decode the recorded

signals then.

- Skip data until all channels are valid

- Use this option if your post-processing software cannot handle 'invalid' values.

When set, the converter will ignore everything in the original recording until all channels are valid.

The reason for a channel being invalid may be manyfold:

- A signal may be transferred very infrequently (low sampling rate),

so after starting the logger, it may take several hundred milliseconds

until all relevant CAN messages have arrived;

- A sensor may be defective, and not deliver data at all;

- Misconfiguration of the logger, e.g. wrong CAN message identifiers.

By default, this option is off which means the converter starts emitting data

immediately, even if "something" is missing at the begin. For text files, missing (invalid) data are replaced by

the 'invalid signal value' as explained further above.

- Combine output into ONE file

- This option can be used to combine multiple input files

(e.g. canlg000.cld, canlg001.cld, canlg002.cld ) into one

common output file (e.g. canlg000.asc in Vector ASCII format).

Note: At the time of this writing (2014-01-22), this option only worked

when converting CAN logfiles into the Vector ASCII format (*.ASC) !

back to top

The CAN logger can optionally record position data (from a GPS receiver)

too. To make use of this GPS-logging facility, you must convert the GPS data

into a format which your post-processing software can handle. The GPS data

can ...

-

be converted into a separate file which can be read into a mapping program

-

written into the output file which also contains the CAN signals (using extra

"data columns" for the GPS data).

Note: This is not possible with DIAdem !

-

Note:

-

You must set the option "Log Data from GPS

Receiver" in the logger configuration, before starting the CAN logger.

This option is disabled by default, because it may cost a lot of disk space.

Furthermore, you must tell the terminal which kind of GPS receiver is connected,

and how it shall be initialized. More on this can be found

here.

While converting data from a logfile which contains GPS data, the GPS track

can be plotted as a preview in a simple map window.

Unfortunately, there is are thousands of different GPS file formats, since

every GPS map software seems to implement their own track format. The CAN

logfile converter only supports the following output formats:

-

NMEA sentences saved in a text file ($GPRMC, $GPGGA only)

-

and another user-defined ASCII format

Fortunately there is a freeware tool called GPSBabel with can convert the

NMEA format into zillions of other formats - most likely, also the format

which can be imported into "your" mapping software.

A few GPS converter options are built inside the CAN logfile conversion utility.

Select the GPS tab to define your required output format:

(screenshot GPS Converter Output Options)

The GPS Converter Output Options are:

-

if logfile contains GPS data, convert the track into a separate file

(which means you will have at least two files in the destination folder:

One for the CAN signals, and another for the GPS track)

-

Track file format

defines the format of the 'separate track file' mentioned above. At the moment,